Discrete-event Simulation

What is Discrete-event Simulation?

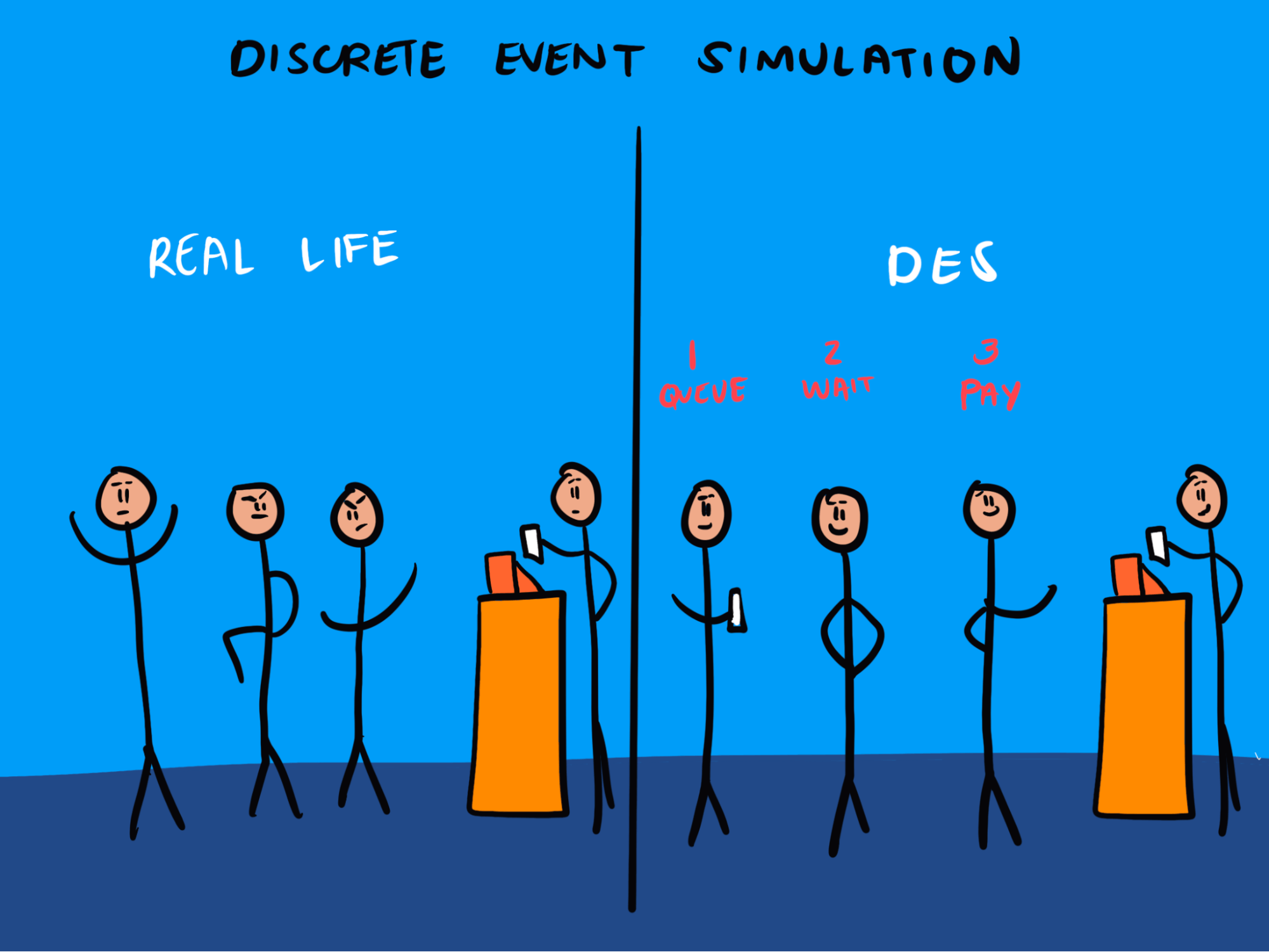

Discrete-event simulation is a powerful analytical modeling technique used to simulate and analyze complex systems where events occur at distinct points in time. Each event—such as customer arrivals, machine breakdowns, or task completions—represents a change in the system's state. This method is widely used in industries like manufacturing, logistics, healthcare, and service management to optimize processes, predict outcomes, and improve efficiency.1

About the Author

Annika Steele

Annika completed her Masters at the London School of Economics in an interdisciplinary program combining behavioral science, behavioral economics, social psychology, and sustainability. Professionally, she’s applied data-driven insights in project management, consulting, data analytics, and policy proposal. Passionate about the power of psychology to influence an array of social systems, her research has looked at reproductive health, animal welfare, and perfectionism in female distance runners.